|

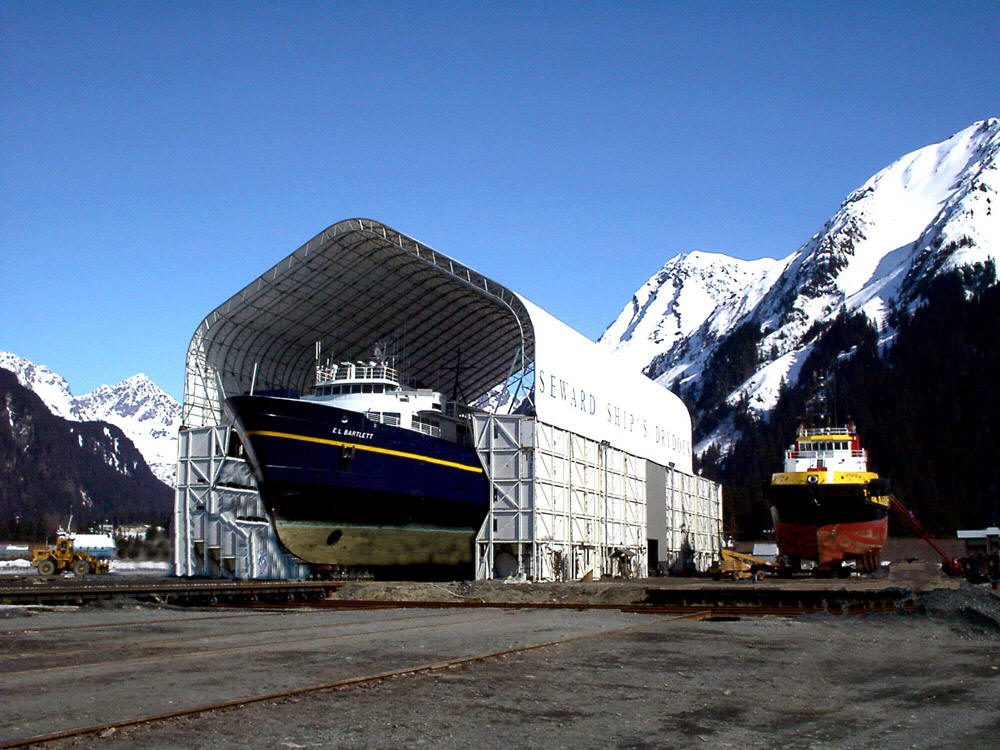

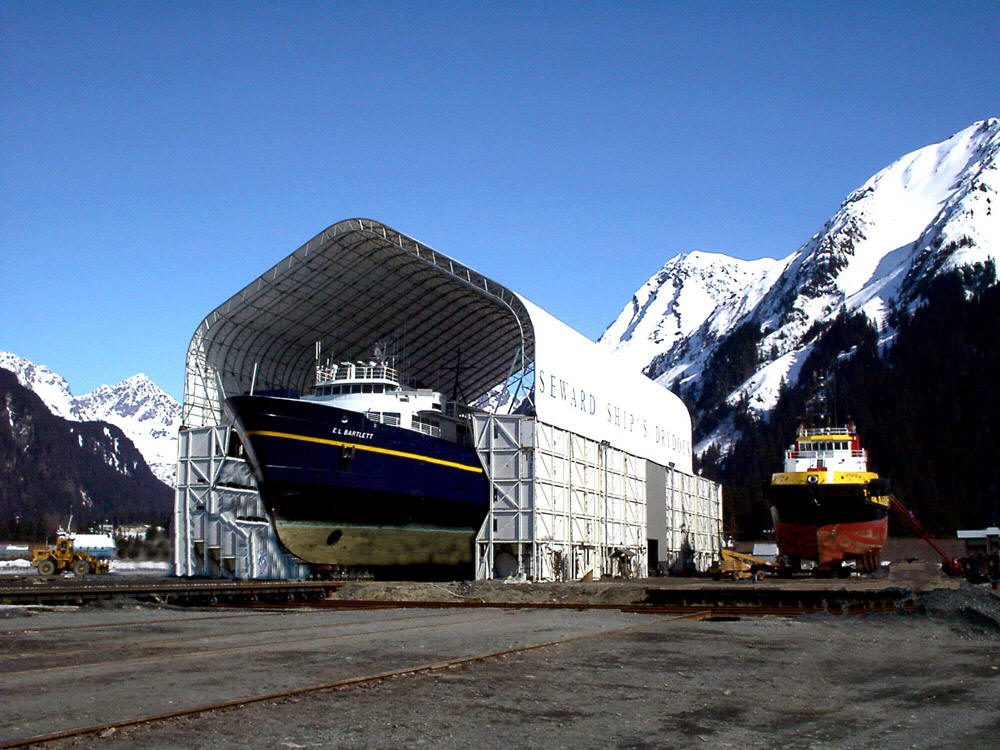

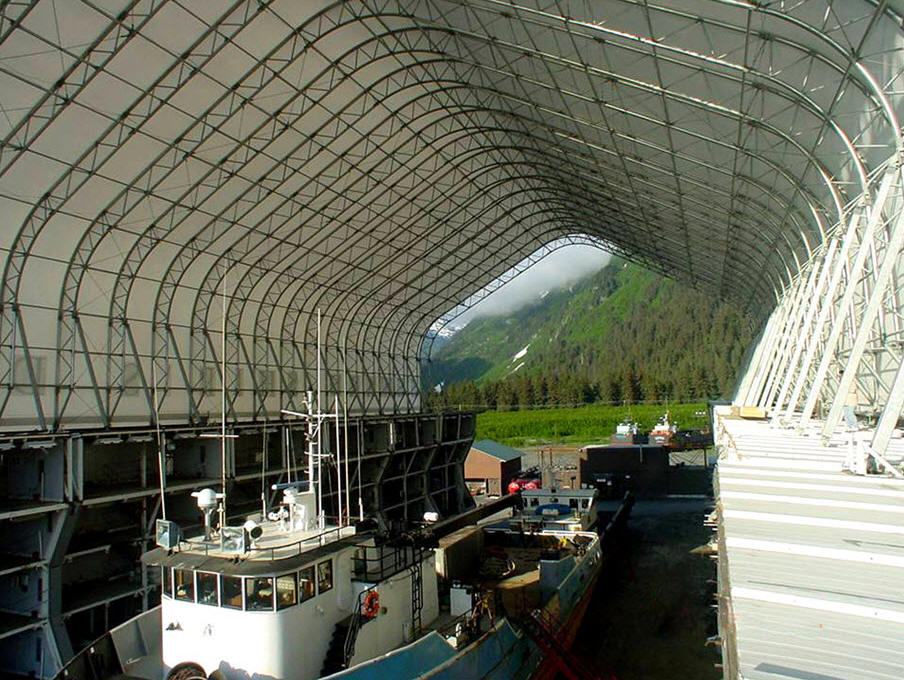

The massive ship dry dock facility is comprised of a 110' by

120' fabric building mounted on a 55' by 220' steel

foundation.

Since Seward

Ship Dry Dock incorporation in 1990, covering the shipyard

so that harsh weather wouldn't affect day-to-day operations

had been a top priority. Finding a suitable building was not

easy. Because of tough zoning requirements including

exposure D, earthquake zone 4, and extreme winds in Seward,

Alaska, the search would span the world for several years.

Discovery of a unique module steel wall system and a fabric

building would come together as the solution being sought.

"Before we

found these types of fabric buildings, three years ago, we

couldn't find buildings that were big enough, that met UBC

(Unified Building Code) and NFC (National Fire Code)

requirements yet were still cost-effective," says Whitman.

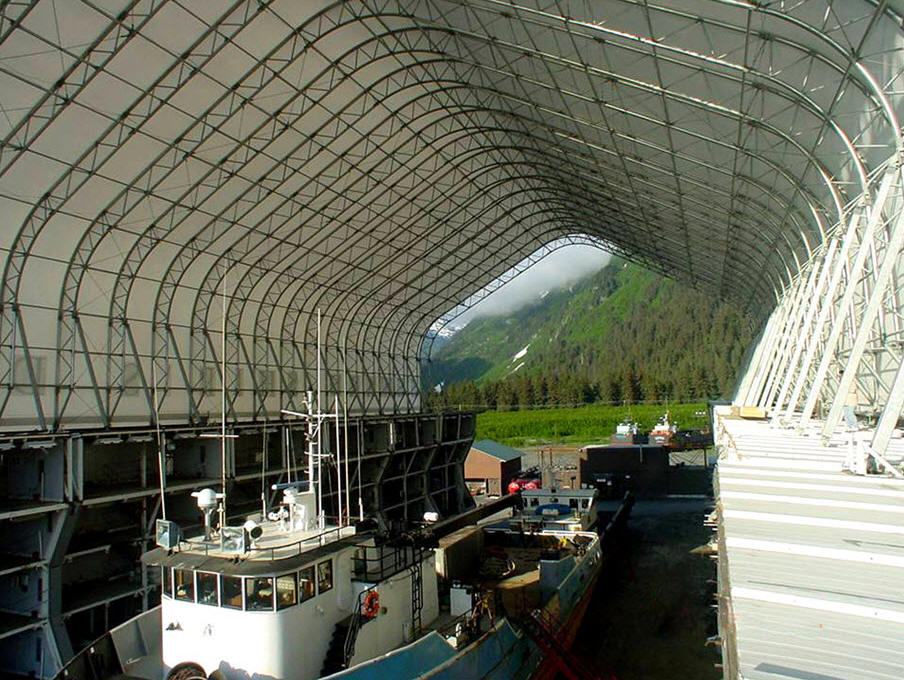

"We service ships from all over the world that are 5,000

tons and 350 feet long, so having adequate room is

important. These types of buildings are pre-engineered

fabric buildings that offer clear-span widths up to 160

feet, to any length, which accommodate a multitude of

industrial applications.

Because of the

unusual installation required for this project, the

installer worked with several companies to plan each stage

of the fabric buildings installation on top of the massive

55 foot high steel wall. "It was an effort from everyone.

If it wasn't for the creativity and ingenuity of the people

involved, this Seward Ship project would never have gotten

off the ground."

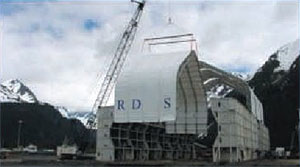

The ship dry

dock fabric buildings steel trusses were constructed in five

separate sections on the ground then lifted by crane onto

the foundation. Once the fabric buildings truss

sections were in place, a specialized winch was used to

position the fabric buildings panels and join the sections

together to complete the buildings cover. The installation

of this fabric building was complete in just 14 days

Since the

buildings construction, it has become a local landmark. "The

city is very pleased with the final look. It was a group and

community effort to complete this project," says Whitman.

Kick out braces were added along the sides of the fabric

building for additional strength to meet the area's tough

zoning requirements.

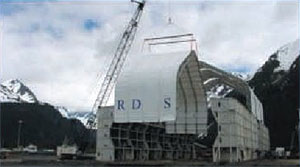

The fabric buildings sections were installed on the ground,

then lifted by crane and mounted on top of the steel wall.

Ship Dry Dock Fabric Building Highlights

Custom Building Features:

•

Twenty-four 15' long by 3/8" thick reinforced steel kick out

braces were added along the sides of the fabric building

for additional strength to meet the area's tough zoning

requirements.

• In order

to achieve the 110' building height needed to service a

ship, custom 12' wall extensions were added to the fabric

building.

Foundation:

• The 55' x

220' steel foundation is submarine enclosure modules that

were going to be used in the process to attach stealth

plating to the sides of submarines; when the process didn't

work, they were the perfect alternative solution for high

permanent walls needed for the dry dock project instead of

steel walls or driving H-beam piles into the ground.

Installation:

• The

heaviest section of the fabric building lifted onto the

foundation was 17,000 lbs, so spreader bars and straps were

certified to meet 51,000 lb. strength tests .

• A crane

was used to lift the steel trusses into place to complete

the building installation. The building has gone through the

full weather test. During one wind storm, the needle on a

wind speed gauge actually broke off and it goes up to 86

mph. The winds must have exceeded 100 mph." Don

Whitman General Manager, Seward Ship Dry Dock Seward,

Alaska.

|