|

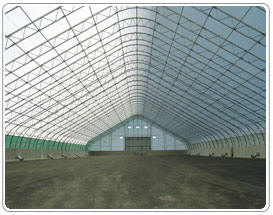

Cargill AgHorizons, Shelton, NE.

160' wide x 600' long Grain Fabric Building

Location:

Shelton, NE

Building Size: 160' wide x

600' long

Application: Grain Storage Fabric Covered Building

Cargill AgHorizons, a

business unit of Cargill, Incorporated, is a

customer-focused organization working to bring

product and service solutions to producers. With

142,000 employees in 61 countries, the company is

committed to using its knowledge and experience to

collaborate with customers to help them succeed. In

2006, Cargill identified the need to store at least

1.5 million bushels of corn / grain at the

AgHorizons site in Shelton, Nebraska. Considering

this tremendous need, Cargill looked to the

fertilizer industry to identify various products

being used for high volume purposes. This is

how the relationship between Cargill and fabric

buildings began.

Matt Richardson is the

FSG Operations Leader for Cargill AgHorizons in

south central Nebraska. "The two main reasons we

chose a fabric building is because of the clearspan

space and the ease of installation," says

Richardson. The fact that the building offered a

permanent solution and would allow operations in any

environment, including wind, rain or snow, was an

instant attraction. Cargill decided to purchase a

160' wide by 600' long grain fabric building with an 8'

wall to store 1.5 million bushels of corn / grain.

Previously, Cargill had

been using large bunkers with concrete or wood walls

covered with tarps to store large volumes of grain

and other commodities. "In the past we always had

grain condensation issues where mold forms on the

corn / grain,"¯ says Richardson. "The purchase of

this grain storage fabric building is a permanent solution without

the cost of a steel structure."

Compared to a steel

building, the grain fabric building offers clear,

open span

space, whereas a conventional building requires

additional support poles. These support poles get in

the way when maneuvering large machinery around

within a building. As well, installation of a fabric

building is typically much faster. "It took just ten

days to go up and it was simple to construct," says

Richardson. "The entire project was 2.5 months and

it would have been at least double the time frame

for a conventional building to be part of the

project."

"The two main

reasons we chose a fabric covered, steel truss

building is because of the clearspan space and the

ease of installation."

- Matt Richardson, FSG Operations

Leader

Cargill is planning to

install a portable conveyor to be used when filling

the structure with corn / grain and will use a

tractor and portable auger to reclaim the corn /

grain by truck. "This was a fun project,"¯ says

Richardson. "It is the first in our division and we

are looking forward to seeing how it works out. This

grain fabric building gives us big space that is

affordable."

"The grain fabric building took just

ten days to go

up and it was simple to construct,"

says Matt.

Installation of the grain storage fabric

building

took just ten days.

1.5 Million Bushels of Corn / Grain

will be

Stored at the Cargill AgHorizons Facility.

|